lifetime access to our service team

services

at your service

our support team

When you purchase from George Stevens, you are choosing world-renowned quality manufacturing that comes with a team that is here to back you whenever you have questions, need support, or need to reach out for service. While our machines are built to last and rarely have problems, if any service or repair requests are needed at any point in the lifetime of your machine, our specialists are more than happy to assist you.

reach out anytime

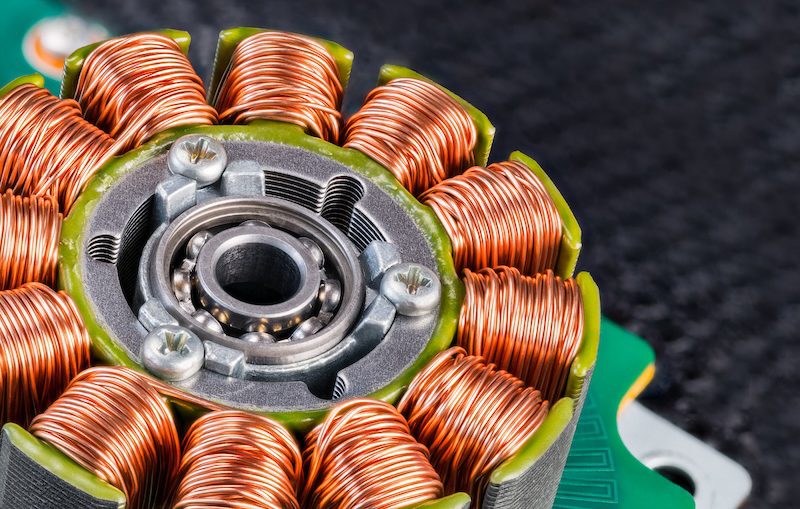

retrofits & repairs

We offer full repair and retrofit service on all George Stevens coil winders, including both mechanical and electrical. Your winder would simply need to come to our facility for a free evaluation.